Menu

Close

- Home

- About

- Products

-

Fixed gas detectorFixed gas detector

-

Portable gas detectorPortable gas detector

-

Gas alarm controllerGas alarm controller

-

Online gas monitoring systemOnline gas monitoring system

-

Powdered pharmaceutical dosing equipmentPowdered pharmaceutical dosing equipment

-

Dosing equipment for gaseous agentsDosing equipment for gaseous agents

-

Liquid pharmaceutical dosing equipmentLiquid pharmaceutical dosing equipment

-

Smart water supply systemSmart water supply system

-

Outdoor integrated smart water supply pump roomOutdoor integrated smart water supply pump room

-

Multi-parameter water quality online analysis systemMulti-parameter water quality online analysis system

-

- Solution

- Case

- News

- Contact

- Home

- About

- Products

-

Fixed gas detectorFixed gas detector

-

Portable gas detectorPortable gas detector

-

Gas alarm controllerGas alarm controller

-

Online gas monitoring systemOnline gas monitoring system

-

Powdered pharmaceutical dosing equipmentPowdered pharmaceutical dosing equipment

-

Dosing equipment for gaseous agentsDosing equipment for gaseous agents

-

Liquid pharmaceutical dosing equipmentLiquid pharmaceutical dosing equipment

-

Smart water supply systemSmart water supply system

-

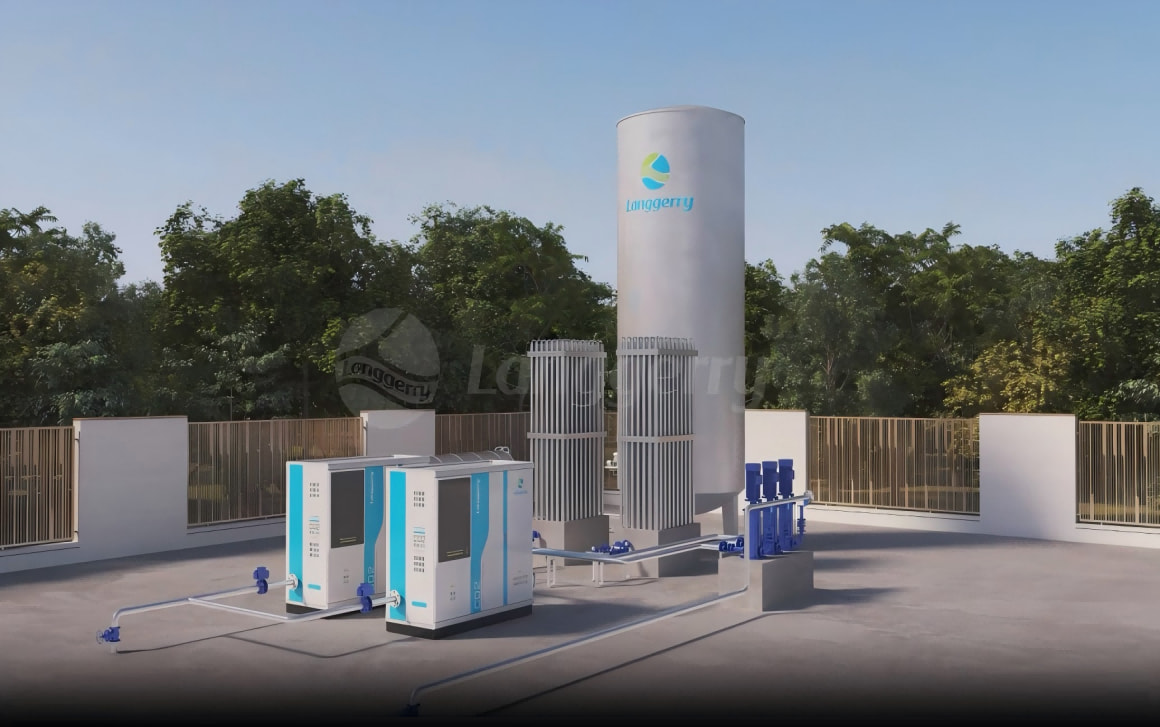

Outdoor integrated smart water supply pump roomOutdoor integrated smart water supply pump room

-

Multi-parameter water quality online analysis systemMulti-parameter water quality online analysis system

-

- Solution

- Case

- News

- Contact